an exclusively VR product comprising the latest hardware and realistic cockpit design

full capability to display and

manipulate all aircraft manuals

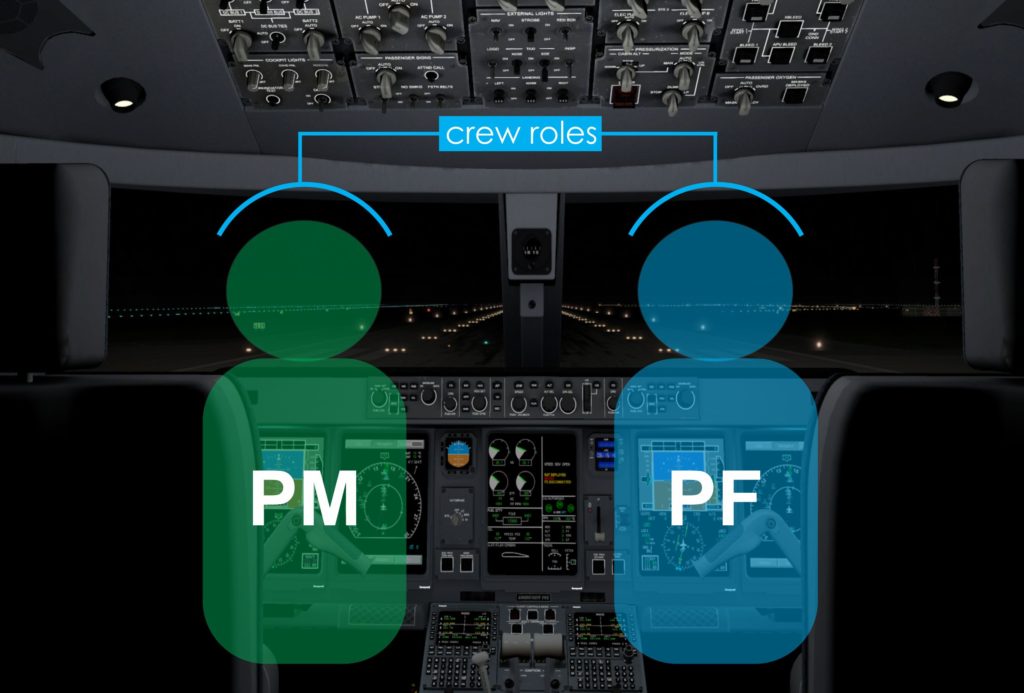

training content provides crew coordination capabilities

Inclusion of the PIT Concept:

theory and practice in a single tempo.

This is achieved by the exclusive Virtual Content Presentation System, through which all content is displayed.

Content development is based on KSA (Knowledge Skills and Abilities), as per EASA guidelines

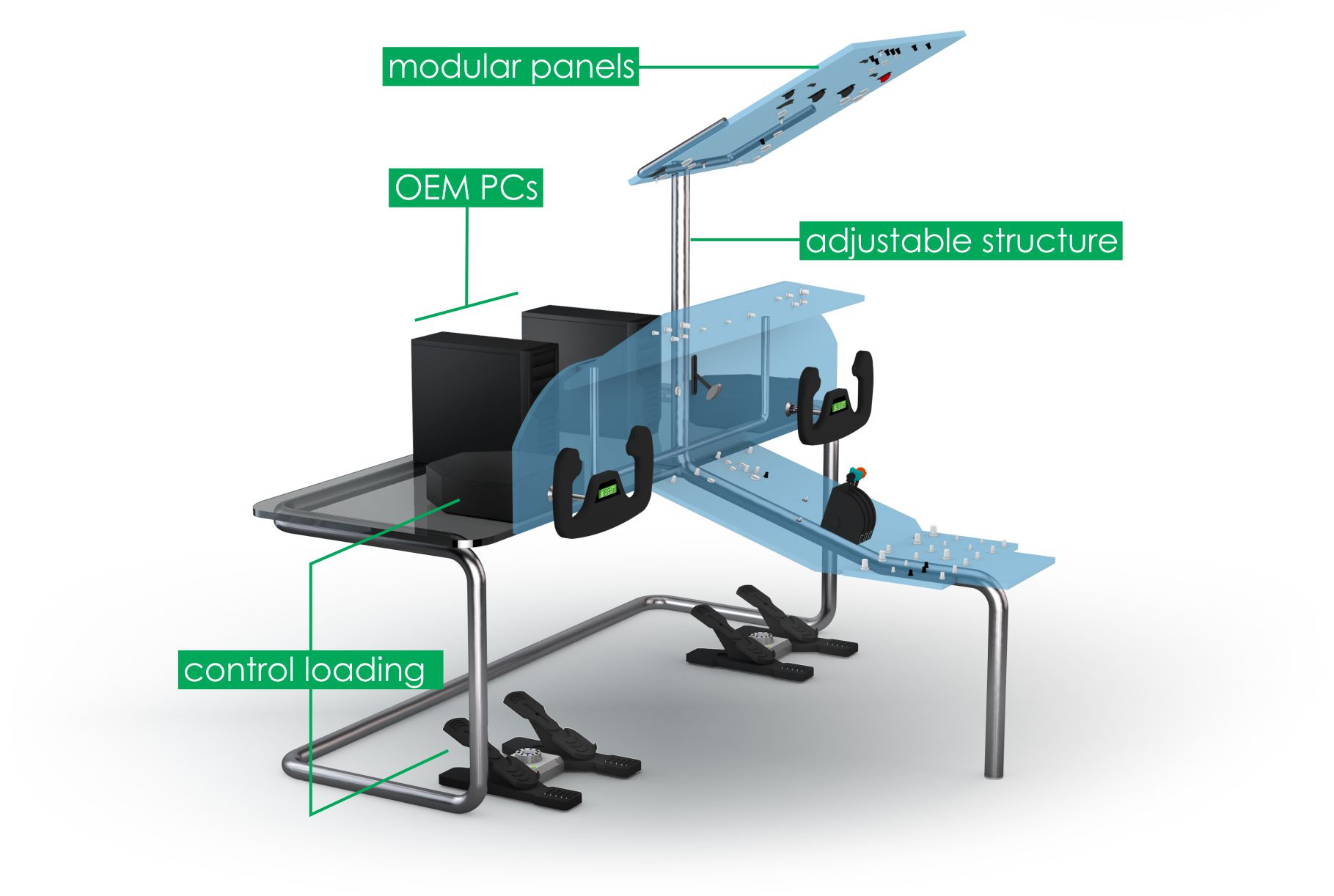

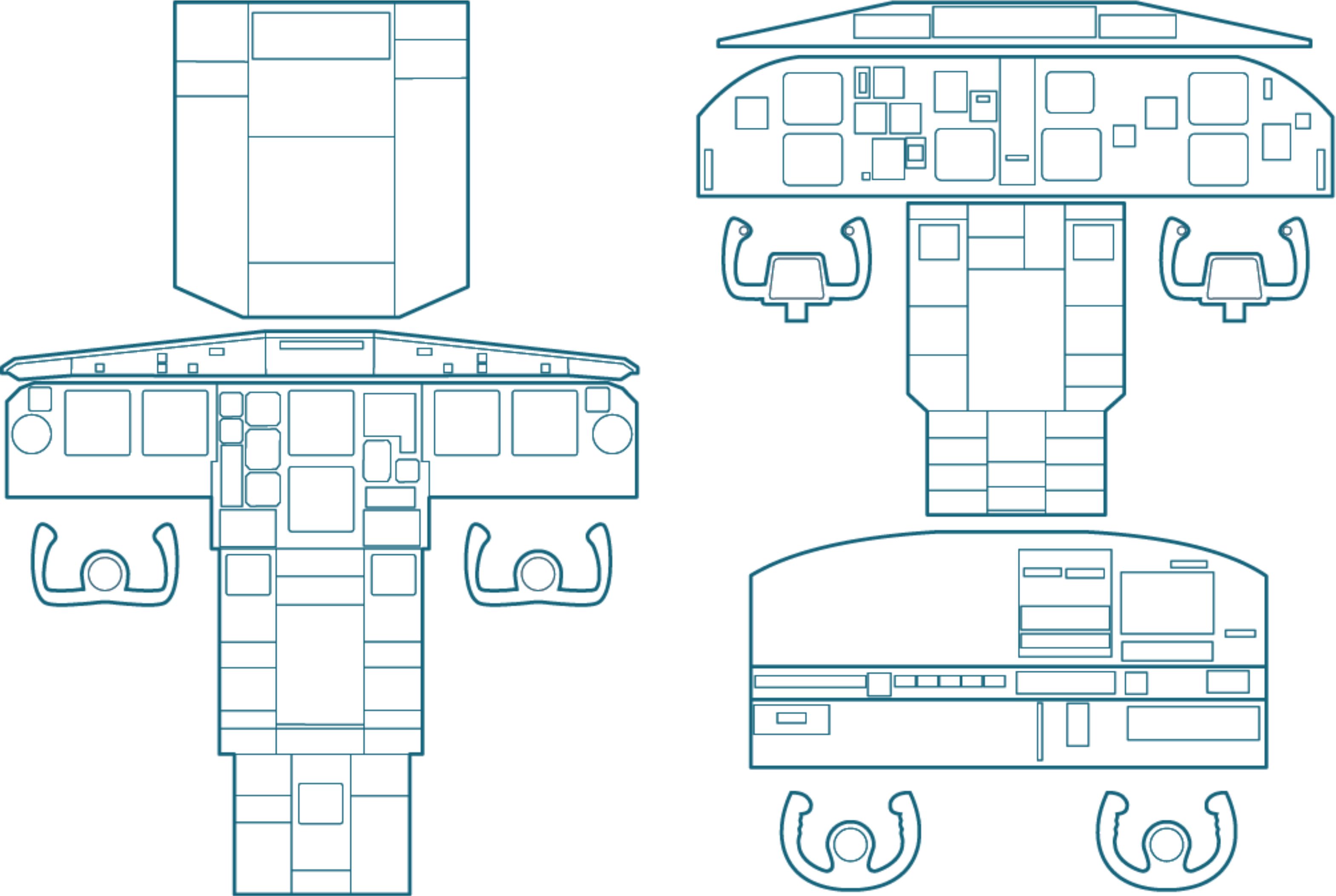

Base Station

(physical layer)

It is the core layer of the Hybrid solution.

Consists of a lightweight and resistant structure supporting all hardware:

- two OEM PCs to handle crew training

- two yoke and rudder sets with electrical control loading units

- adjustable panel support structure to adapt to any aircraft ergonomics

Projection

(virtual layer)

This is where physical meets virtual. The best of two worlds.

- an HMD with a 3D stereoscopic cockpit projection, superimposes the virtual cockpit layer to the physical one, generating a fully realistic and immersive 360 degrees experience,

- natural interaction with cockpit controls with full tactile and force feedback

- the VCPS provides the means to integrate theory and practice in a single tempo

- full flight simulation capability

Modular Panels

- no physical instruments/displays

(lowest maintenance and ownership costs) - only switches for tactile feedback

- 5cm thick and lightweight

- wall rack storage

- quick link assembly

- wireless I/O with Base Station

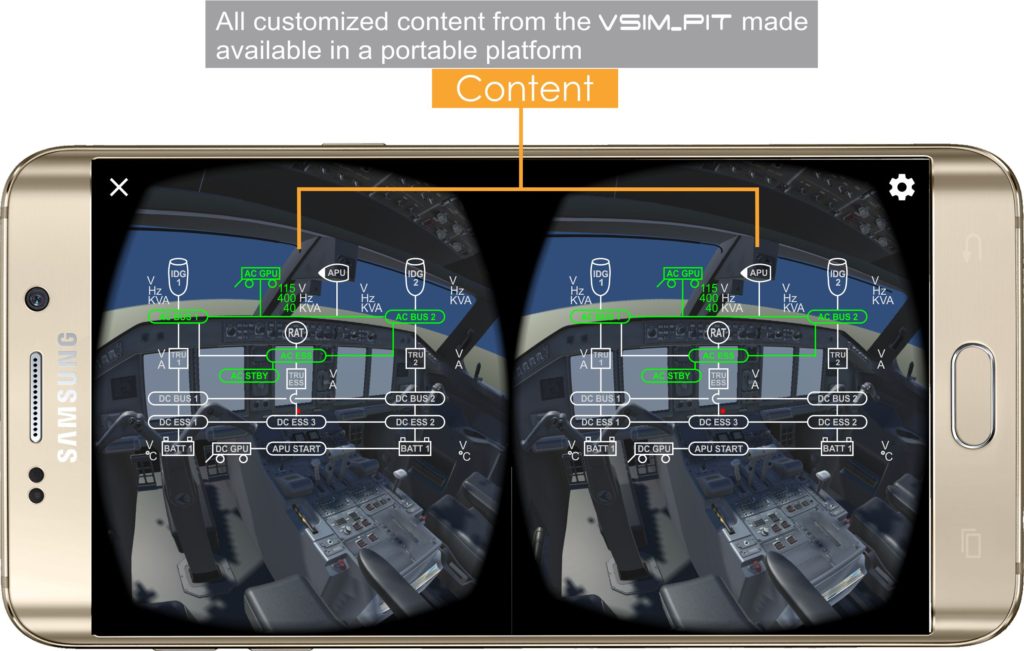

Leveraging the portability, processing power and HD displays of smartphones, the V_smart provides the means for trainees to consult, review and interact with the same content provided by the Vsim_PIT

All content with 3D stereoscopic projection for complete immersiveness.

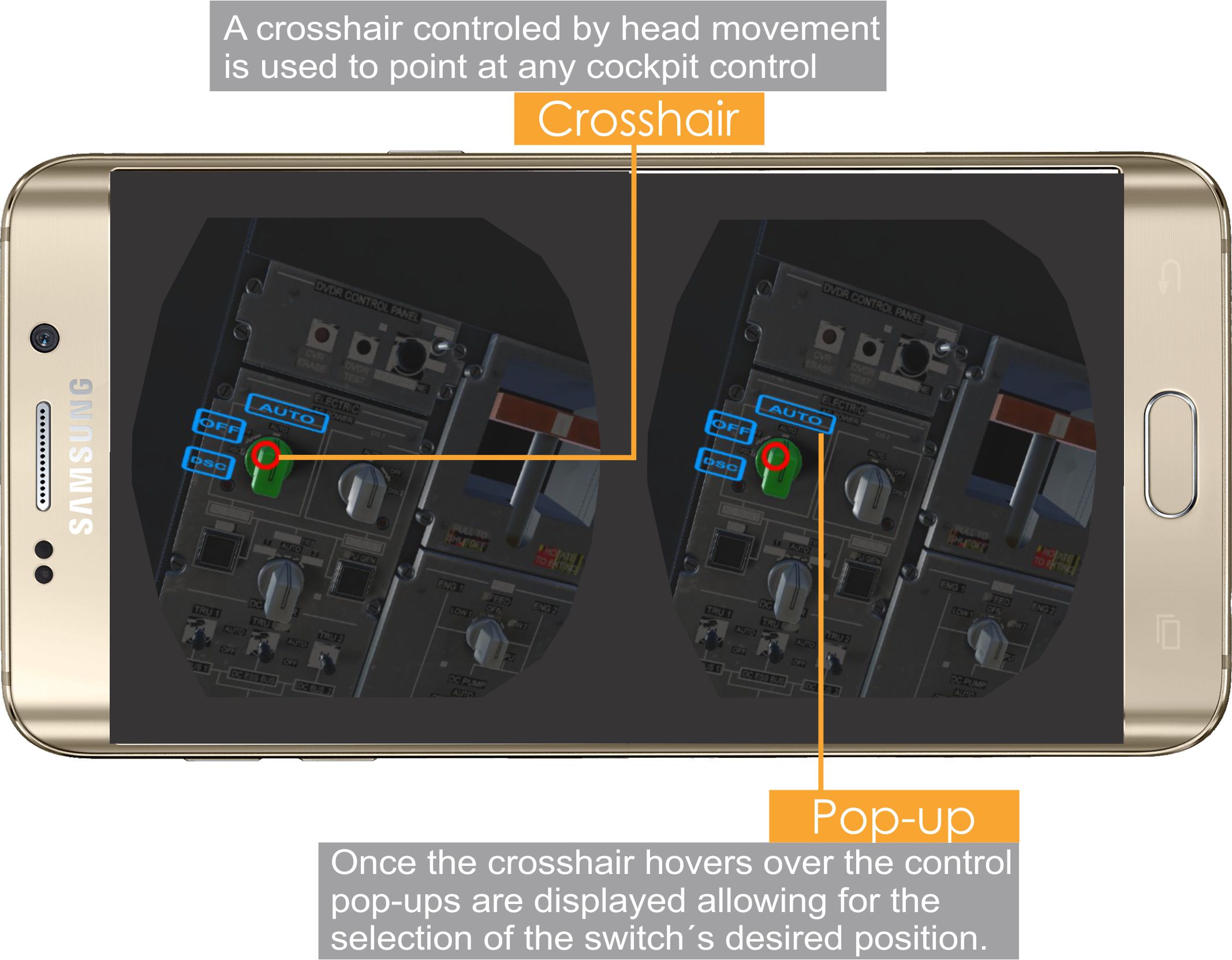

Cockpit controls are actuated by a head movement tracking crosshair. Selection of each control´s position is performed by choosing from one of the pop-ups

maintenance training

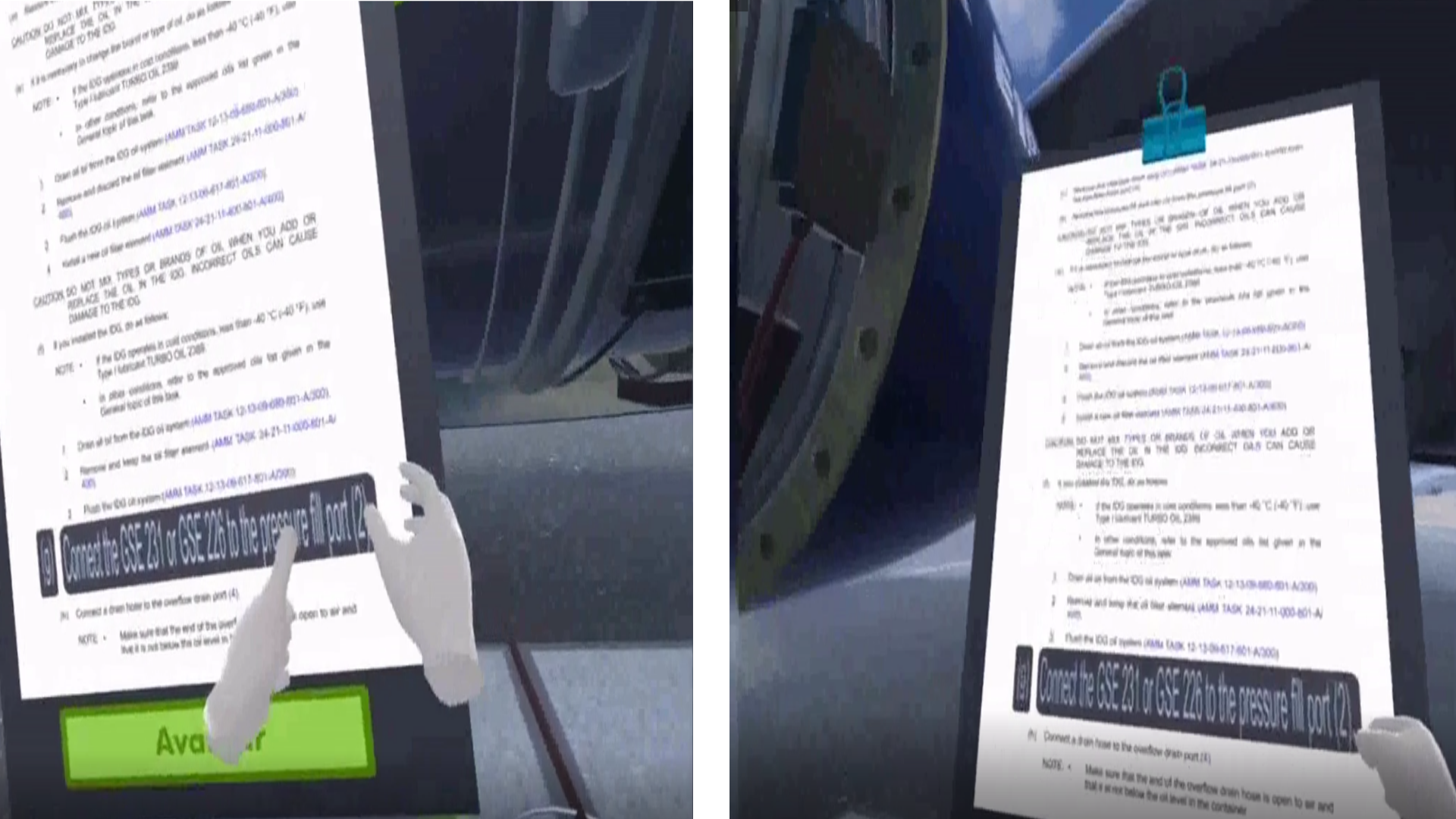

Boosting 1832 x 1920 pixels per eye, Oculus Quest 2 is our chosen tetherless platform for maintenance personnel training. It´s latest firmware puts away the controllers thus allowing for a more natural handling of tools, parts and manuals within the 3D space, using your own hands instead.

tools handling

manipulate all tools in a realistic way in your work space following the step-by-step instructional audio provided by the courseware for each specific maintenance task

manuals

reposition the manuals to fit your working location and flip through their pages freely

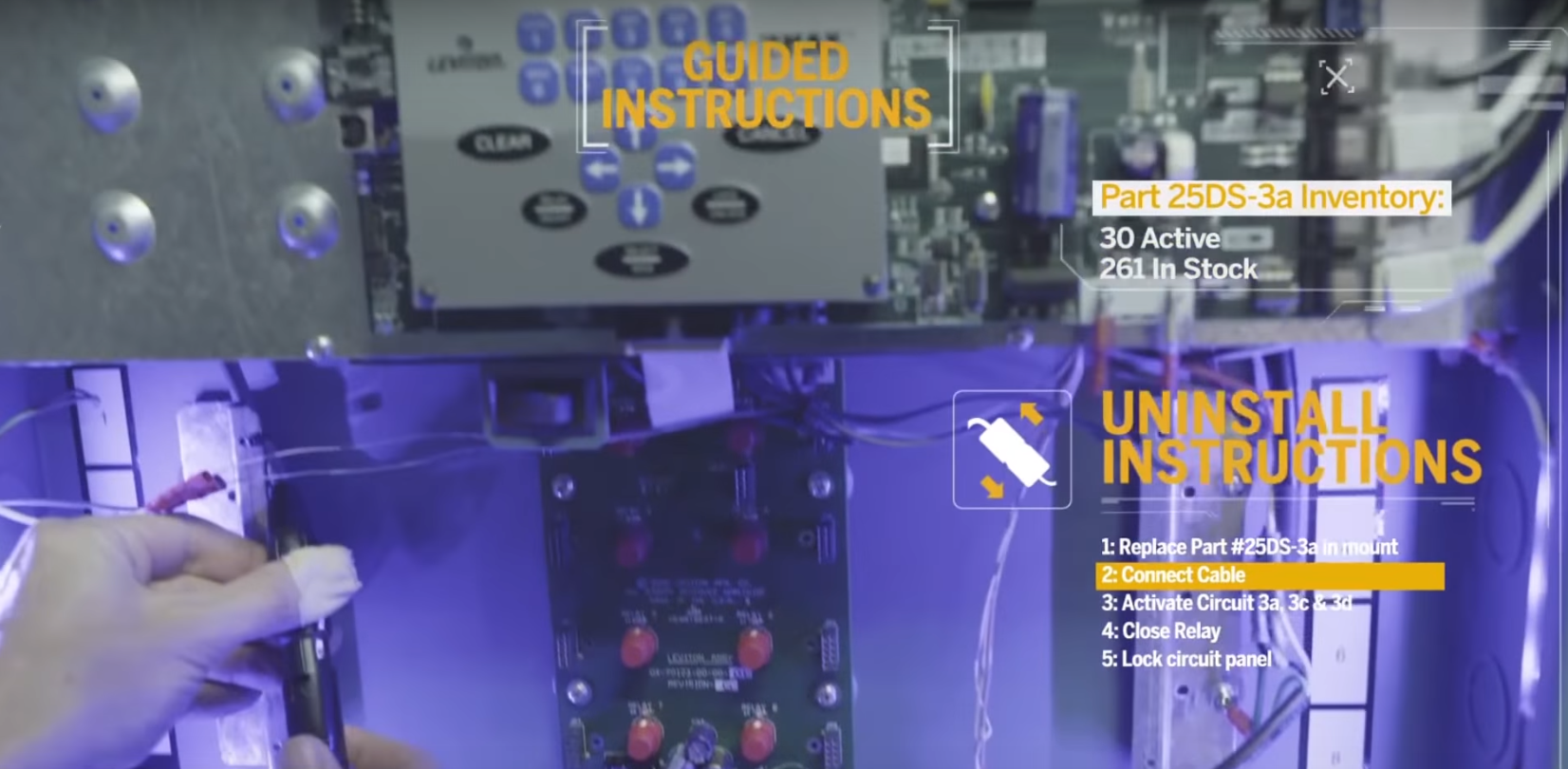

maintenance and field service

Turn your customer’s technician into your field diagnostic team while sharing all aspects of the tasks he is performing, via real time two way audio and video contact with your central engineering or any other department.

Paper copies are are cumbersome and pose security risks. Access electronic copies on the fly, via voice commands and keep your both hands free to safely execute required tasks.

capabilities

- Capture and record in-field video

to document task´s execution,

ensuring traceability and

Quality Assurance - Real time check of inventory,

per item on the checklist - Assembly instructions

overlay the technician’s real-world

experience to increase accuracy - Heads-up and Hands-free

execution of tasks - Printout of executed tasks

for physical signature - Real time check of updated SBs

and procedures for specific

tail number

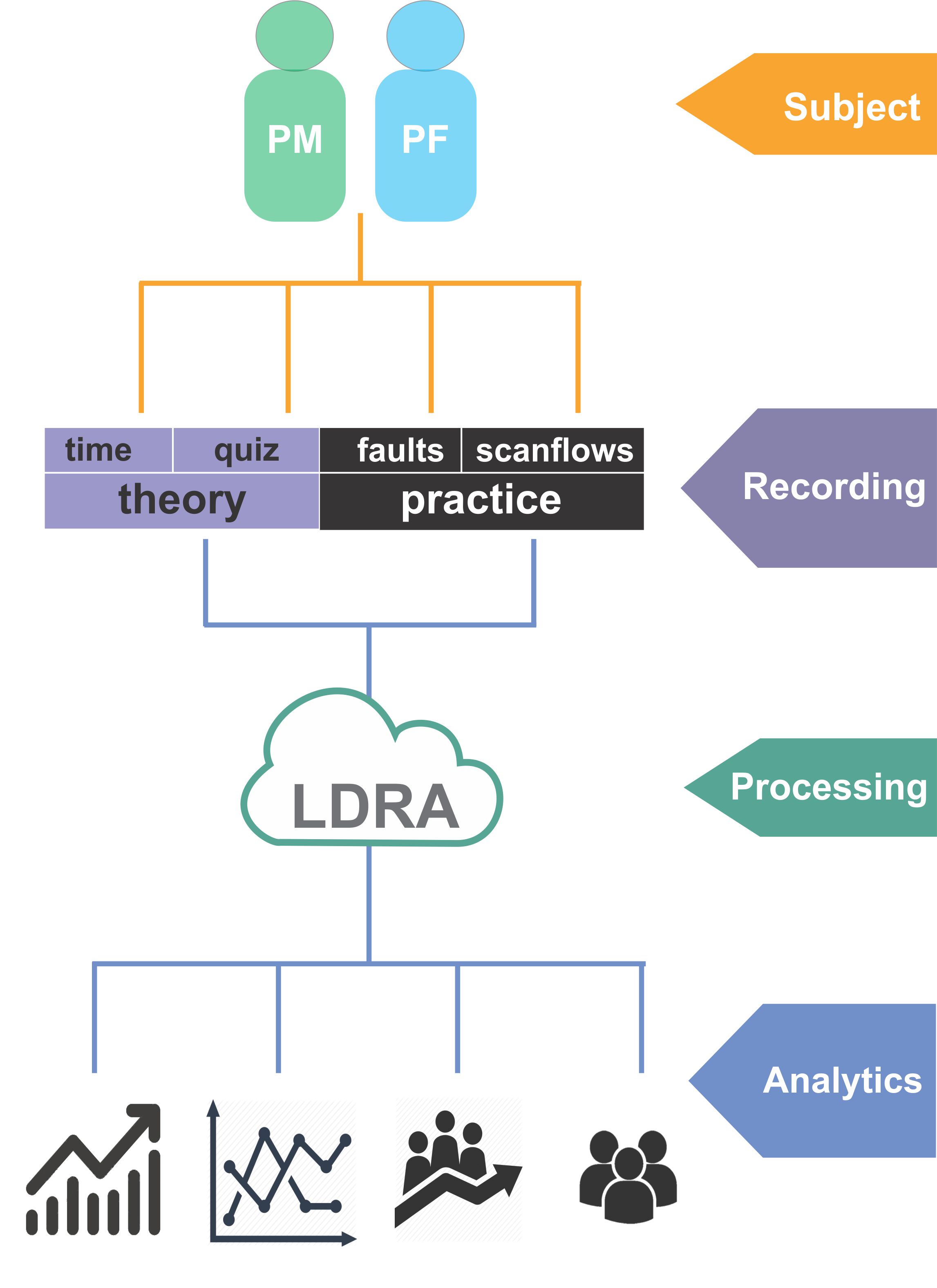

LDRA

the Learning Data Recorder and Analyzer is an exclusive trainee quality control tool. The ultimate learning black box. It is applicable to both flight operations as well as for maintenance training coursewares. All user´s actions are tracked, recorded and analyzed during training sessions, making sure that SOPs and/or the company´s training program is strictly followed.

This tool is designed to be used on both Vsim_PIT and Vsim_HYB products

- the subject

individuals or crews; - recording module

consists of the V_Monitor module which acquires in real time all commands performed on switches, toggles and levers, as well as on manuals manipulation,

and

V_Feedback module which provides real time feedback messaging, of incorrect actions performed during company established scanflows; - LDRA

V_Scenario sub-module triggers predefined configuration files to implement failure situations in a randomic and automated schedule.

- analytics module

provides user´s practical knowledge (scanflows and fault resolution) analytics;

and

user´s theoretical knowledge (probing questions) analytics;

Overall performance

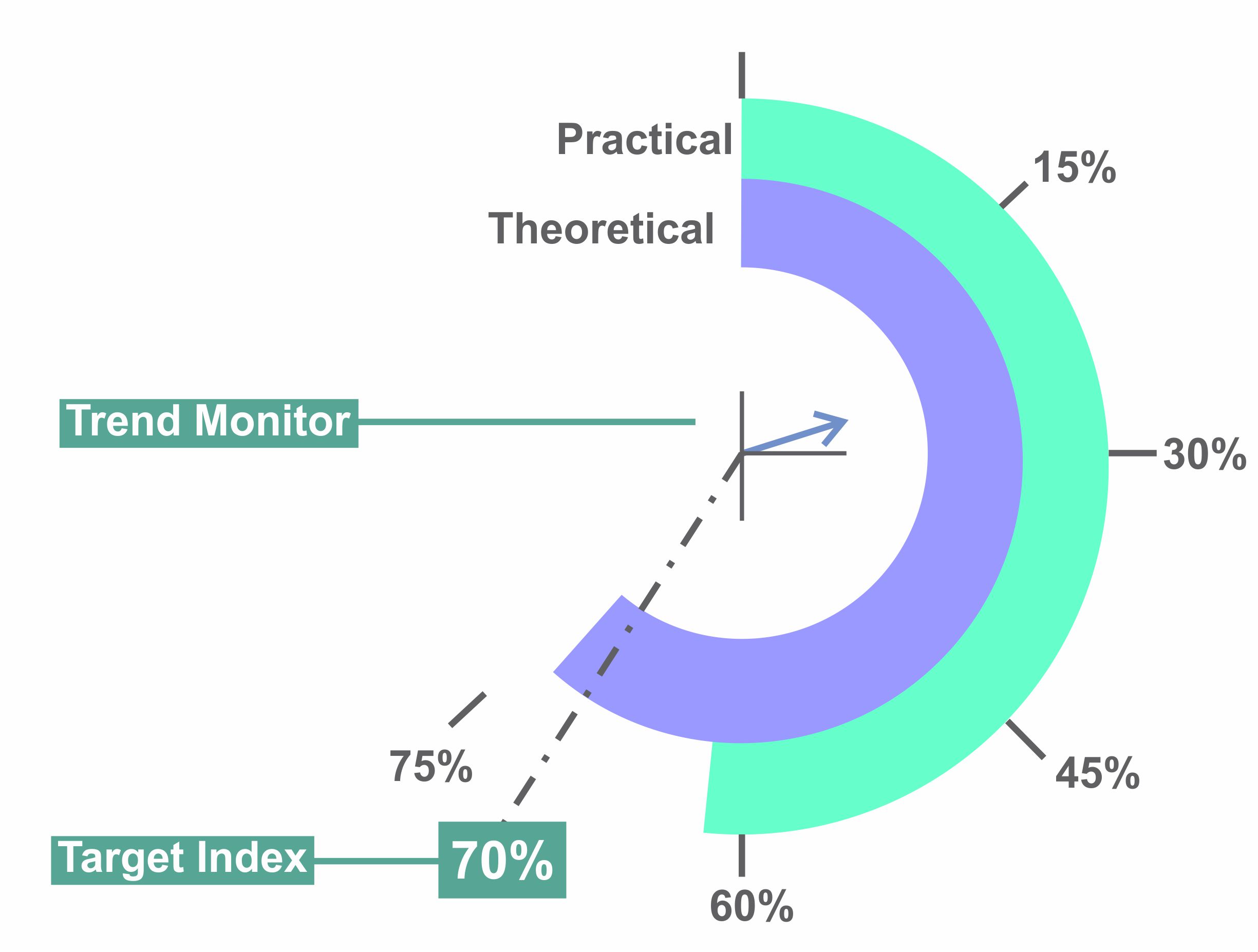

- Trend monitor

compares training crew results with all crews in the database and indicates any difficulties - Target index

defined by the training department as the

minimum score for trainees to progress to the FFS - Practical column

measures the user´s hability to perform according to the SOPs - Theoretical column

measures the user´s aircraft systems theoretical knowledge

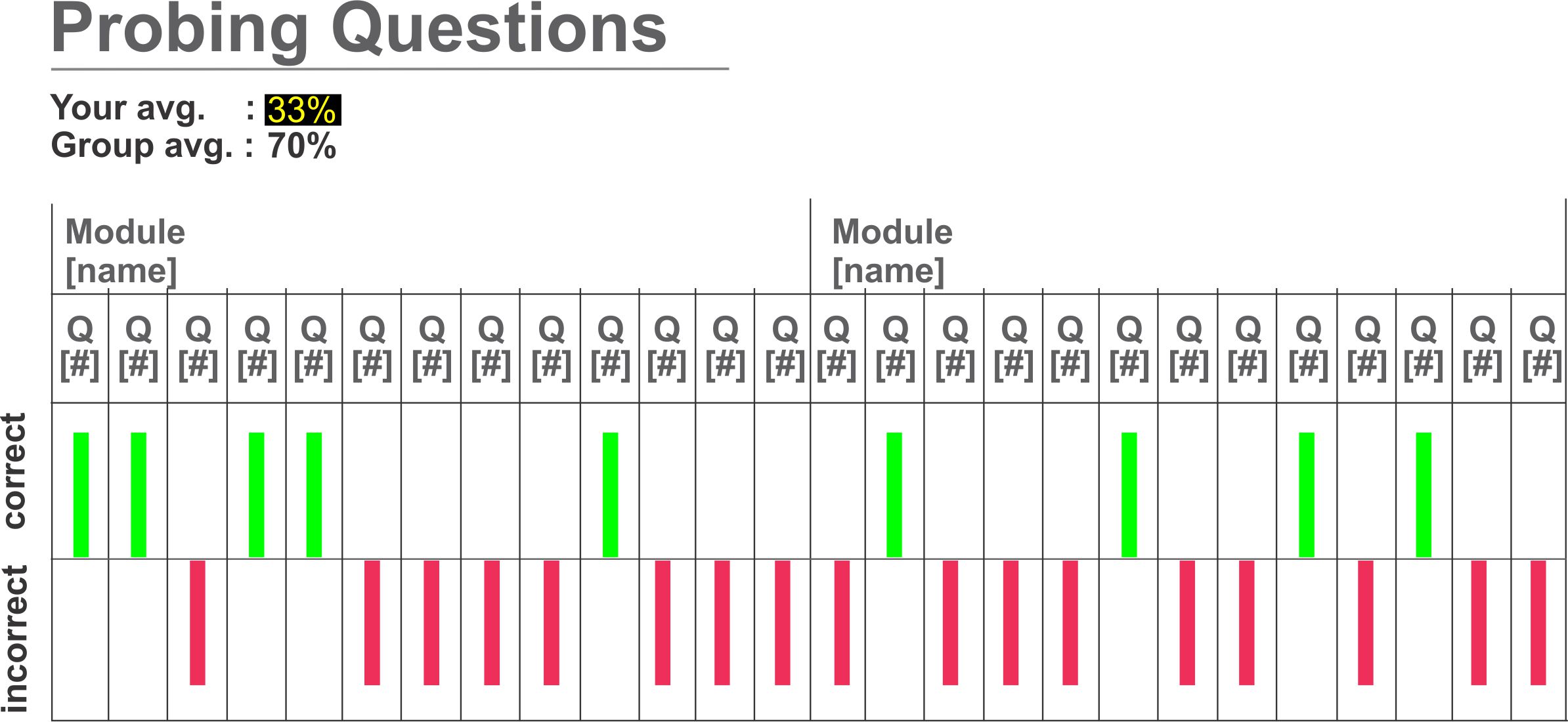

Theoretical (1)

displays user´s progress in terms of system´s knowledge, evaluated via the presentation of probing questions along the course duration and compared with the group´s average

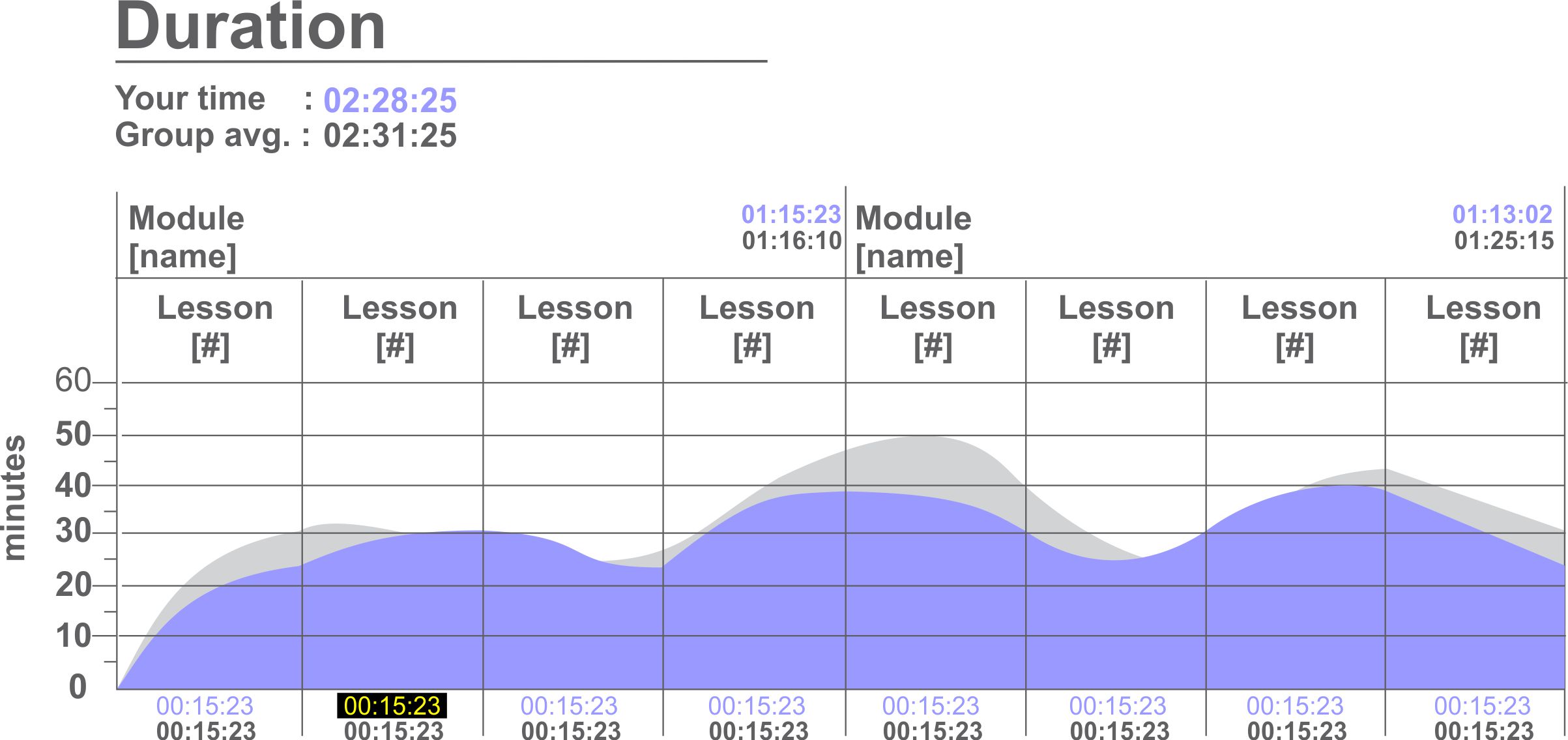

Theorectical (2)

displays user´s time to complete each lesson and module, compared with the group´s average

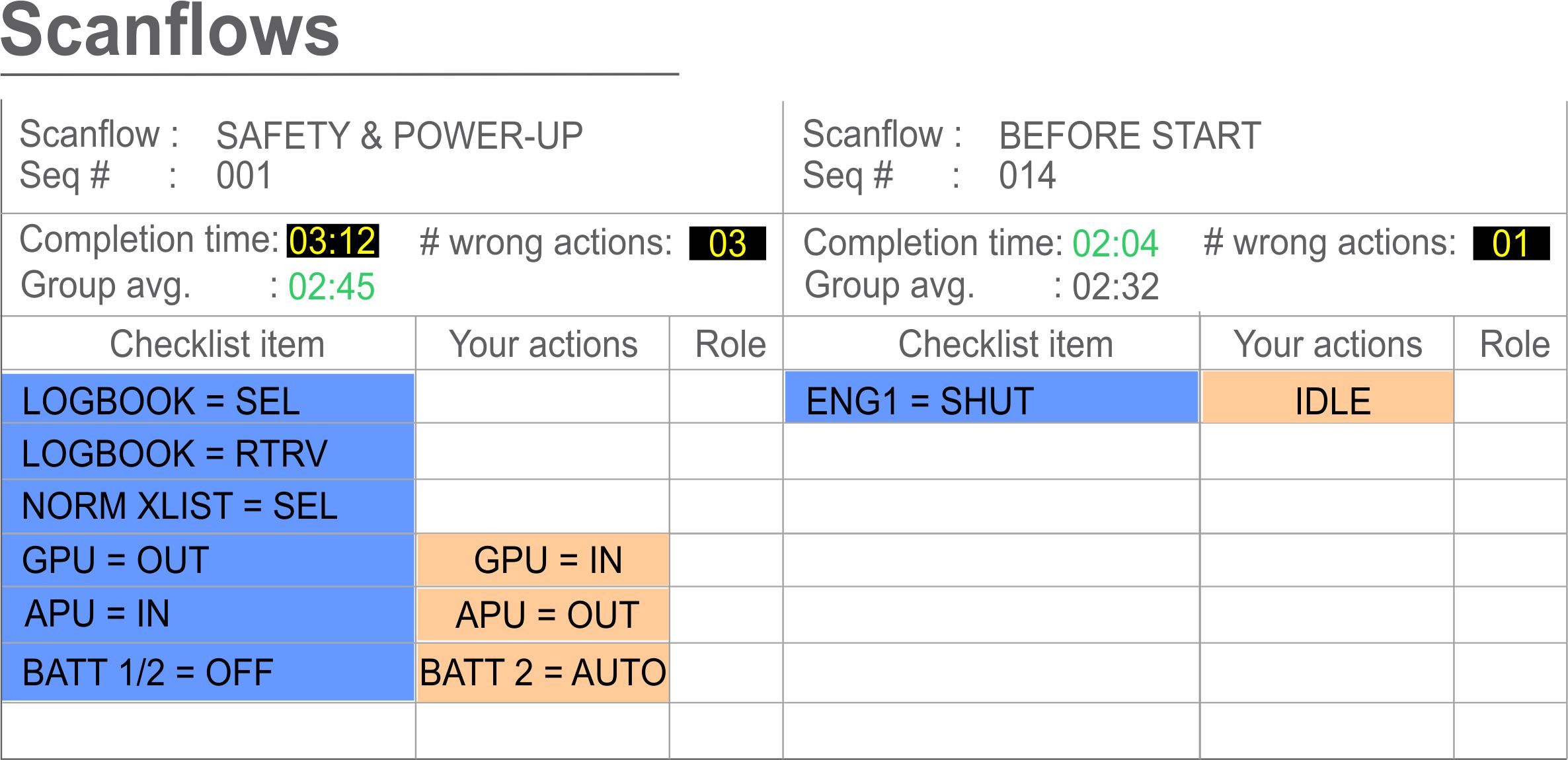

Practical (1)

displays user´s actions while performing normal scanflows, considering crew primacy (captain, first officer, first in cockpit, pilot flying and pilot monitoring) and compares actions performed by each crew member with those established on the approved manuals

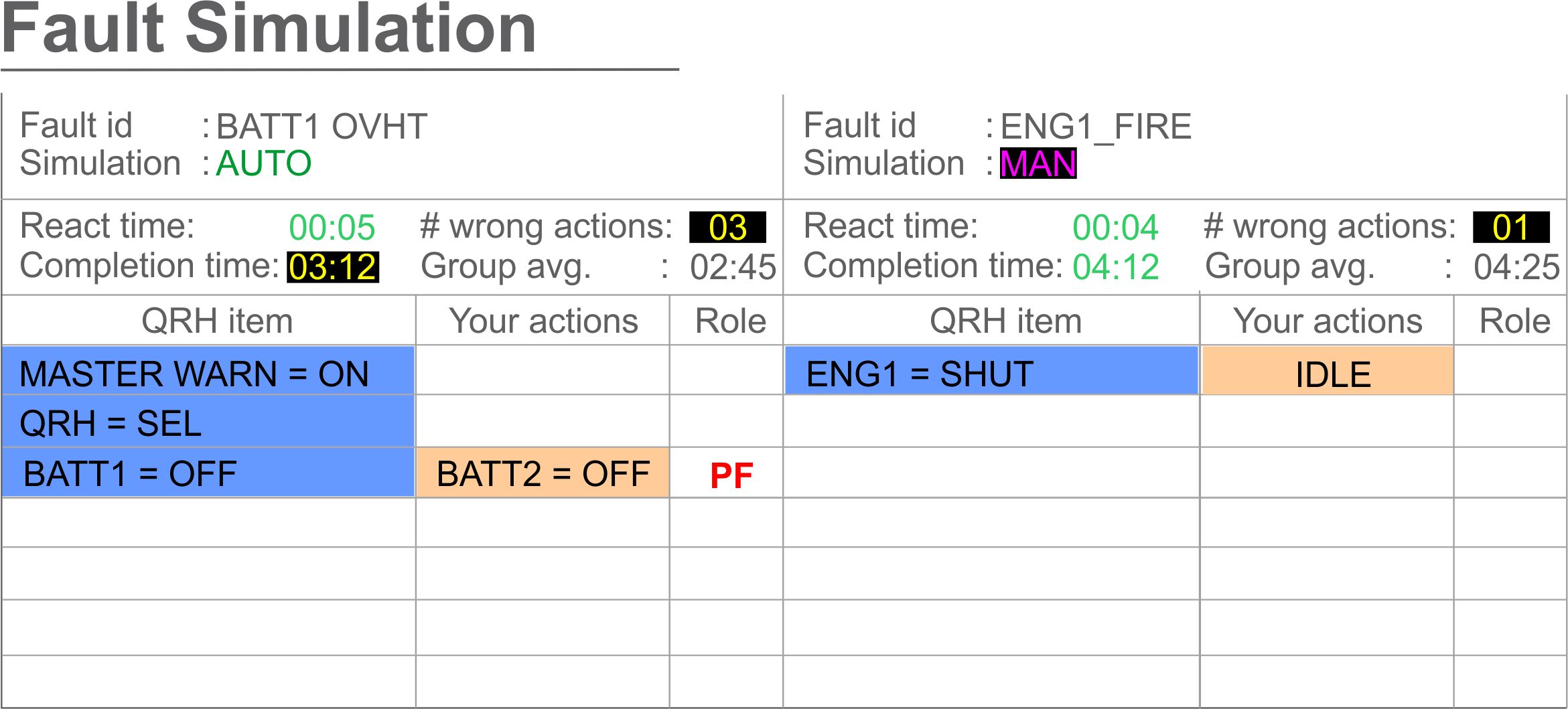

Practical (2)

displays user´s actions while performing abnormal/emergency fault resolution, measuring reaction and completion times comparing performed actions with those established on the approved manuals